Installing a new boiler can be a massive undertaking, and without proper planning, it can quickly become a major headache. Modern boilers are safer, more efficient, and easier to operate than their predecessors, but once the boiler is installed, it can be much more expensive to fix mistakes that should have been caught in the planning phase. Keep in mind that state and local regulations are there to keep you safe and should be followed. Also, if you are unsure of any steps in the boiler installation process, contact the State Boiler Inspector or the experts here at Tate Engineering.

Where’s It Going?

One of the first steps in installing a new boiler is determining where it will be going. Will the boiler be inside in a mechanical room or outside on a pad? Will the old boiler have to be decommissioned and removed before the new boiler can be installed? Even well-planned boiler change-outs can take four months to complete, so it is important to know when the project should start in order to minimize impact on the facility’s operations.

Although it may seem obvious, ensure that the dimensions of the new boiler will fit in the space you’ve picked out. Newer boilers are generally much more efficient and take up a much smaller footprint. Once the boiler’s new location has been established, you can move on to verifying that the rest of the boiler’s requirements will be met and if not, add them to your change-out plan.

Related: Tips for Installation Projects

Fresh Air Source

Outdoor installations make this step easy, as the boiler can just pull the unrestricted fresh air surrounding it. If the boiler is inside, make sure that it has access to an unrestricted source of fresh air. If the air will be coming into the room through louvered openings on the wall, check that these openings are sized large enough for all of the air that is needed. If the louver uses motorized dampers, inspect the damper’s operation so that the boiler won’t try to run while the damper is closed. Poor air flow is a bad thing for boilers. If the air flow is too low, the burner will lose efficiency, generate more carbon monoxide, and can potentially create an explosive situation.

Get the Exhaust Out

Outdoor installations make this step easy too. Getting the fresh air to an indoor boiler is only half the battle. After combustion occurs and heat enters the boiler, the combustion gases have to be directed out of the building and away from the boiler. Gas flues have to be constructed in such a manner that they don’t create too big a restriction for the boiler. Having a smooth gas flue with gentle turns (use 45 degree transitions instead of 90 degree where possible) helps to keep the pressure drop through the ductwork as low as possible.

If multiple boilers will be using the same exhaust ductwork, make sure that the ductwork goes up in diameter after the individual boilers connect. If the diameter does not change, pressure drop will go up and combustion rumbling and severe pulsations may occur. Condensate drains are also important in long runs of ductwork. The National Fuel Code does a great job of outlining best practices for laying out the ductwork of exhaust gas flues and can be a very helpful resource.

Gas Train

Undersized gas trains will prevent the boiler from operating as designed, reducing its efficiency and potentially limiting its capacity. When sizing the gas train, think about how many pieces of equipment the gas train will be serving. The size of the pipe must be big enough to provide the quantity of gas, at the pressure required, to each piece of equipment. During construction, it is not uncommon for sediment or debris to get into the gas train. Before running the boiler, make sure that the gas train is cleaned out and any filters in the gas train are cleaned. Using a drip leg before the equipment fuel train is also important for limiting problems in the future, such as debris clogging a valve.

Tuning and Safety

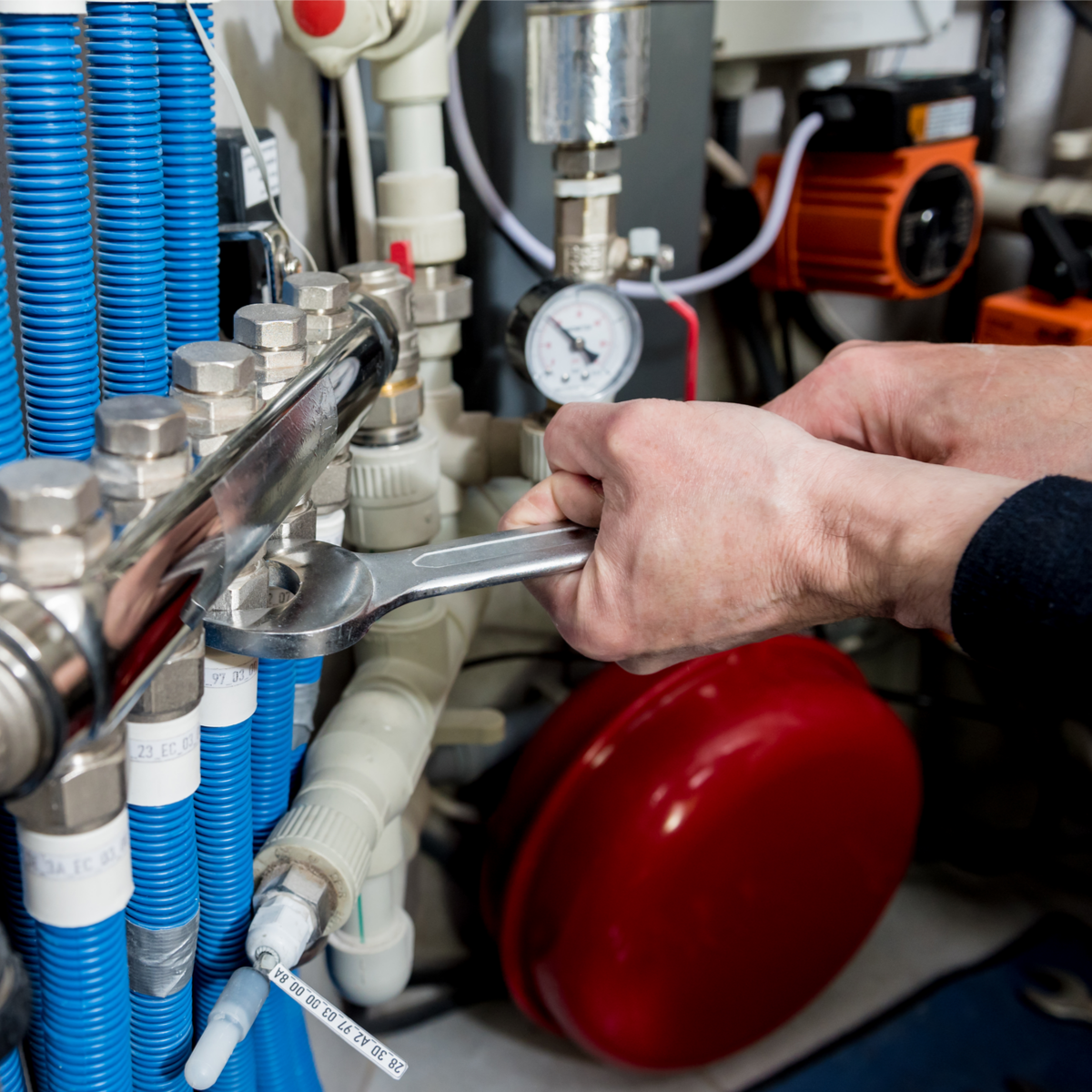

Once the boiler is installed, it needs to be tuned, and the safeties must be checked before it is ready for full operation. Tuning a boiler based on the color of the flame just isn’t accurate enough. A combustion analyzer should be used to measure the NOx and CO in the exhaust gas and tune the boiler appropriately. The setpoints for when the boiler turns on and cuts off need to be checked and adjusted too in order to keep the boiler from short cycling.

The safety check is arguably the most important part of a boiler installation. Check the level control switch to make sure it is turning the boiler on and off appropriately. Pressure relief valves need to be operable and in good condition. High and low gas pressure switches need to be checked and adjusted to keep the boiler operating inside of the manufacturer’s specs.

Once all of the safety checks are completed, you should be left with a brand new boiler that is ready to operate safely and efficiently. Careful planning helps make the process go much more smoothly. With the proper preventative maintenance, your boiler will last for many years to come. For help with boiler installations, and getting the right kind of boiler for your facility, get in touch with Tate. Our expert engineers are always ready, and we can assist with our knowledge of installation process requirements and local codes.